Maintenance: Servicing Shell & Tube Heat Exchangers

Peter’s Machine is proud to service shell and tube heat exchangers for manufacturing, energy, and other industries. We provide a wide variety of applications based on the most suitable design and materials to ensure a cost efficient and reliable solution. The full range provides standardized product lines for an optimal price/quality ratio as well as customized designs for the most demanding duties in oil & gas, power generation, marine, refrigeration and many other industries.

Shell and tube heat exchangers, as their name implies, are devices that move heat from one fluid to another. Heat exchangers collect heat released by chemical or burning processes in factories. Through these exchangers, energy expenses can be saved by a company, and are necessary for the operation of many industries.

If you have never had this equipment serviced or replaced in the past, you need to check in with a professional. Shell and tube heat exchangers require regular care, including fabrication and machining of parts as they undergo natural wear and tear over time.

Get A Quote Today

We have served the following industries for the past 35+ years:

- Healthcare & hospitals

- Manufacturing

- Commercial real estate

- Government buildings & institutions

- Power plants, renewable energy

For a full list of industry partners, see this list.

Parts of Shell and Tube Heat Exchangers: What to have Serviced

Shell heat exchangers have numerous advantages over other types of heat exchange systems.

The first advantage is the accommodation of condensation or boiling heat transfer in either the tubes or the shell, making the device operate regardless of its orientation. Second, pressures can be varied widely, and thermal stresses can be accommodated efficiently. Lastly, the materials used to construct these devices are highly flexible to accommodate corrosion and other concerns. The shell and the tubes can be made of different materials.

This type of exchanger comprises a shell containing a bundle of tubes and is sealed at each end by a tube sheet that isolates the tubes & shell. A fluid flows through the tubes, whereas another one flows through the shell. This causes heat to transfer through the tube walls. The set of tubes is called a tube bundle and may be configured differently to accommodate different types of operations, fluids, pressures, or requirements. For example, fabricated exchangers can meet the demands of high temperatures and pressures.

Our team mainly works on the tube bundles and baffle components of the exchanger itself. If the shell chamber or tubes need cleaning, inspection, or maintenance, we can assess your needs and make improvements as well.

Adhering to Your Industry Standards

It is important for us at the shop to maintenance and deliver products that abide by the exact standards you require. While there are many different variations of shell and heat tube exchangers, we can ensure that any modifications or replacements will stick to its original design.

When you contact our staff about bringing in a machine for servicing, we will help you obtain all of the necessary information needed to complete the job. Our Drilling and Machining Price Quote Form is the best way to specify the dimensions of your heat exchanger. If you are unsure of these measurements, call the number on our site. Someone at our shop will be happy to assist you.

Fabrication, Drilling, Machining

Metal fabrication, drilling, and machining require a variety of equipment and expertise. Our staff are trained professionals and are specialists when it comes to shell and tube heat exchangers. Not sure if we have the machines needed to work on your issue? Read through our list of equipment on-site.

-

Large CNCs

-

Small CNCs

-

Horizontal Boring Mills, Vertical Lathes

-

Horizontal Lathes

-

Large and Small Radials

-

Support Equipment

See some of our services here:

Tube Sheet Drilling

Tube Sheet Reaming

Transporting Implement Parts

We have the equipment to create efficient machines that will surely meet your requirements. You can depend on our services in any of the following:

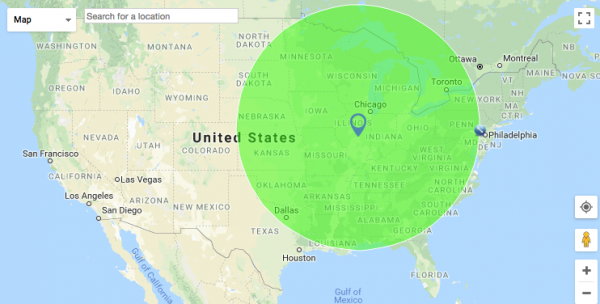

On-Time Delivery for businesses and organizations near Decatur, IL. We operate within a 700-mile radius of our shop, meaning that we can supply and transport equipment all over the eastern and southern United States. If you are not sure whether your business is located in our service area, contact our shop and we will be able to coordinate a pick up.

-

Heat Exchanger Machining

-

Dryer Plate Drilling

-

Shell and Tube Heat Exchangers

-

Distributor Plate Drilling

Contact us today for questions. Peters Machine is the name to trust for professional, local work in central Illinois. Our shop efficiently provides fabrication for businesses nearby.